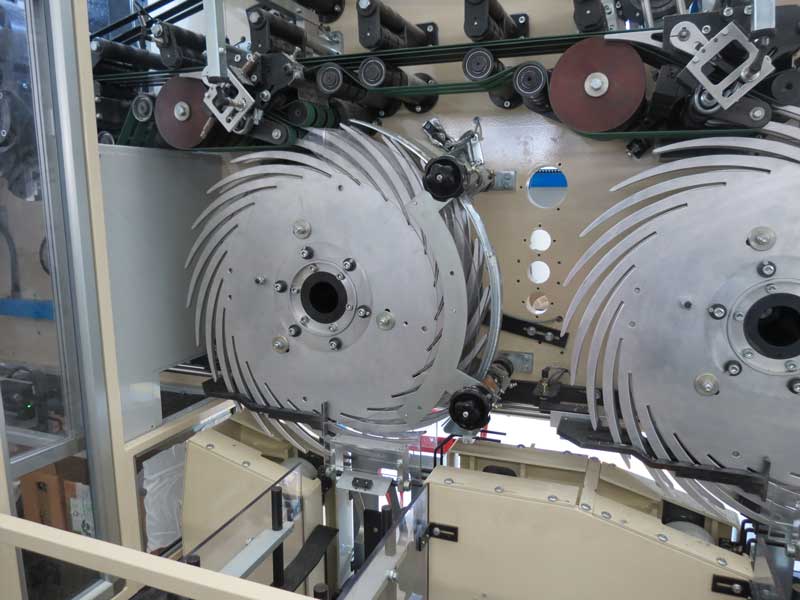

The AS Line of tissue converting machines are modular solutions for the production of large volumes of multi-fold paper towels characterized by excellent performance, technological innovation and cost-efficient operation. The presence of highly automated folders allows the production of interfolded, continuous interfolded with glue and overlapped towels. The ‘Fasten Pack’ technology - gluing the tail of the first packet to the head of the second one - offers significant advantages for users and manufacturers thanks to the elimination of discontinuity in extraction. In such a way the machine allows obtaining a high productivity and packets having a large volume, without giving up the extremely easy use.

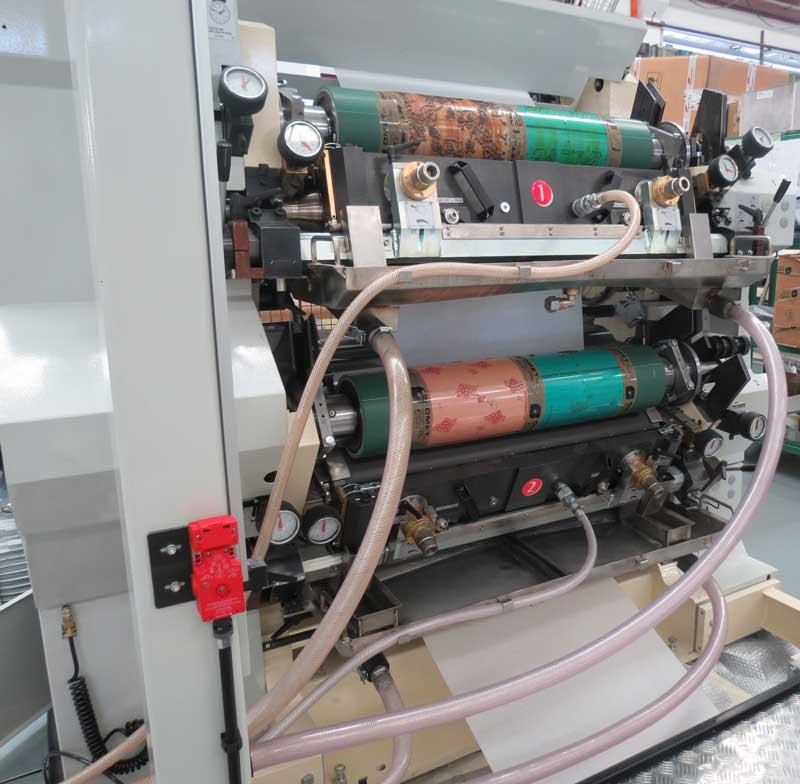

As part of the project of digitization of its machines, OMET has completely renewed in 2014 the offer of the AS Line for the production of paper towels. The machine, which can process coils from 2600 (104’’) to 3600mm (144’’) wide, has been fitted with a new unwinder and an innovative DESL laminator as well as advanced controls, even remote to ensure a constant production flow and reduced machine stops for maintenance. The DESL lamination group consists of 2 cylinders with 350 mm in diameter and 3 meters in length, with two incisions that work in sync to produce embossed towels (nested). The system involves a rather high reduction of waste especially in the start-up phase and considerable savings of time normally spent for manual adjustments.

| AS Line | |

| Рабочая ширина | 3,100мм (124'') |

| Число дорожек | 2 to 15 |

| Флексопечатные секции | 1 - 2 печатные секции |

| Макс. диаметр рулона | от 1,800мм (72'') до 2,500мм (100'') |

| Материалы | От 1 до 3-слойные ткани, бумаги, уложенные воздухом, нетканые материалы и слоистые материалы |

| Тип фальца | 1/4, 1/8 and 1/8 с дозатором складкой |

| Открытый формат макс. | 30x30cм (12''x12'') |

| Открытый формат мин. | 20x20cм (8''x8'') |

| Механическая скорость | 300 м/мин (2800 fpm) |

| Макс. непрерывная производительность | 4,000 – 6,000 штук/мин |